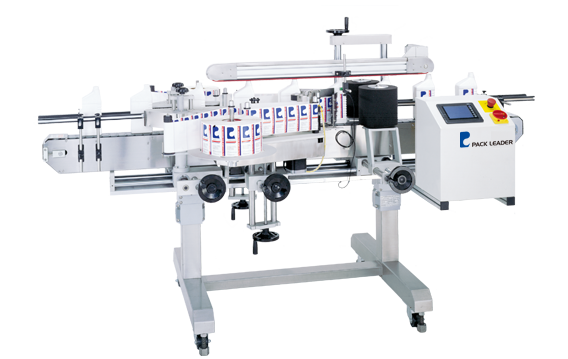

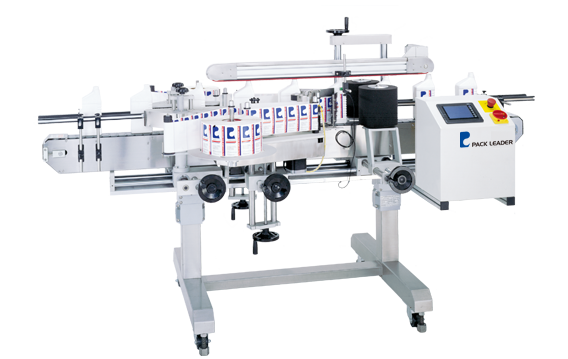

PL-622 Two Sides Labeling Machine

Model Number: PL-622

Accomplish more at ease, saving time, and increasing profit.

High Speed, High Efficiency, High Stability

Additional Value Of Production Efficiency

PL-622 front and back automatic labeling machine uses a touchscreen control system for easy setting, besides offering high speed, high stability & accurate labeling to be distinguished by its excellent production efficiency in combination with low investment costs, outstanding product characteristics and higher industry competitive capability.

Excellent Flexible Mobility Quality

Regardless of standalone unit or as part of an integrated production line, PL-622 front and back automatic labeling machine provides the best arrangements on machines.

Simple tool-free adjustments for the guide rail, side pressure guidance units, the applicator of PL-622 front and back automatic labeling machine allow you to accommodate different shapes of products and the hand wheels make it easy to adjust. Suitable for various production lines, regardless of working as a standalone unit or as part of an integrated production line, it provides the best arrangements on machines to bring the maximum efficiency and flexible mobility. PL-622 front and back automatic labeling machine uses a touchscreen control system for easy setting, besides offering high speed, high stability & accurate labeling. This labeler is distinguished by its excellent production efficiency in combination with low investment costs, outstanding product characteristics, and higher industry competitive capability.

The conveyer front section is equipped with a side pressure device that can guide the bottle straightforward and separate bottles into equal distance in order to conveying smoothly and label accurately. Castors and threaded leveling feet are installed on the chassis for greater mobility to bring out great benefit. Besides, this labeler could optionally be equipped with a printer and turn table of feeding and collection.

PL-622 front and back automatic labeling machine is an essential manufacturing partner. Its extra value of production efficiency and quality is so excellent that no one could replace it.

Machine Structure

- Precise Labelling Control

Powered by a microstepping motor and controlled by a microprocessor system the PL-622 efficiently achieves highest accuracy. The conveyor, side and top pressure also use the same power to maintain a stable labelling. - Modular Design

The structure of the labeller is modular, and all components are standardised and unified. The parts can be easily adapted to different requirements and bring out the best efficiency. - Flexible Mobility

The mobility castor and stainless steel fixing nut are designed to flexibly move the machinery to support another production line. Therefore, it would boost the invest benefits. - Quality & Beauty

The main structure is manufactured from S304 stainless steel with anodized process and high quality aluminum. It complies with the GMP standards which provides easy maintenance and a long durable life. The upper chain made of FRP chain material and the durable UPE guide rail used for the conveyor system is designed to protect the appearance of the product and ensure efficient performance. - Simple Adjustment For Labeling Applicator

It provides a low or high width adjustment by being equipped with hand wheel mechanism for easy adjustment of the applicator. - Rigid Machine Base

The double foot stands are made from stainless steel. It is steady and does not take a lot of room. When the labeler is working, it does not quake or affect the labeling action.

Machine Device Features

- Side Pressure Device

In-feed product alignment system maintains consistent product position and separates bottles into equal distance. - Top Pressure Device

Simultaneous top pressure is applied to carry the products and confirm that the body of the bottle is stable. - Pressure Roller Device

With a specially selected sponge to adhere the label tightly to the bottles without deforming it by over pressing.

Operation & Functions

- Easy Operation

PLC based on Personalize control panel with a large and advanced touchscreen. Easy to learn control panel for simple intuitive operation. - Built-In Instructions And Trouble Shooting

The built-in instructions reduce personnel training time, allowing the users to learn and operate at the same time. It provides flexible time arrangement for personnel to attain the most efficient production and obviate the necessity of personnel reassignment. The built-in troubleshooting assists operators to find prompt solutions to operation problems, helping avoid shutdown costs by finding quick solutions. - 30 Lots Cross Memory Module

Record the best labeling settings for the best productivity. It is convenient for each production line with multiple products. Even for different user, it would also get into condition quickly. - Smart Label Length Setting Function

Quick set counter for desired length and perfect positioning of label. - Missing Label Set

Prevent product mislabeling to ensure a product accuracy during the production and fulfill production QC procedures. - Production Preset Function

A built-in counter can either run freely keeping track of the number of products labeled to control the production or it can be used in batch mode where the labeler automatically stops when the desired number of products have been labeled for efficient production management. - Auto Labeling Start Up Mode

When the power is switched on, the machine will enter the labeling settings automatically for the same production as the previous run with no need for further setting. This mode can tremendously save the operator’s time and increase the production efficiency - Eight Synchronized Speeds Selection

Enable dispensing speed and conveyer speed fully synchronized for the most precise labeling effect. - Labeling Delay Function

It is ideal for small scale adjustments and can do digital calculations for dispensing speed and position. It offers quick and easy set up through its advanced touchscreen control in addition to its clean, precise and accurate labeling applications. - Strict Quality Control

The Pack Leader products are manufactured under strict ISO 9001 quality control procedure and also strictly tested by the European CE standard and UL and perfectly meet their safety quality regulations.

Contact Information

Find us here:

ADR AG

Ludwig-Wagner-Straße 19

Wiesloch

69168

Germany

Phone: 06222 938823