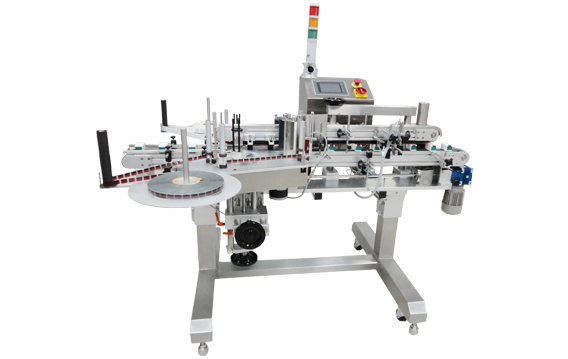

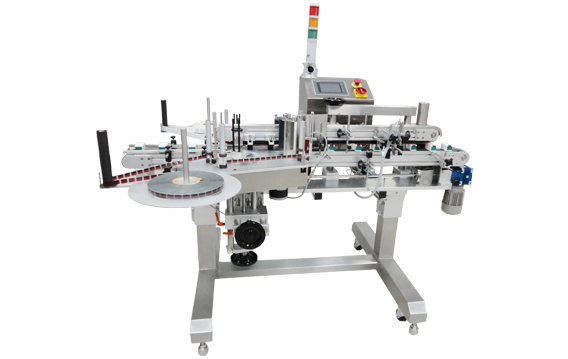

PL-252 Corner Wrap and Tamper Proof Labeling Machine

Model Number: PL-252

Accomplish more at ease, saving time, and increasing profit.

High Speed, High Efficiency, High Stability

Fast & Precise Corner Labeling Option

PL-252 Corner Wrap & tamper proof automatic labeling machine is suitable for corner labeling for various carton box products. Adapt inline continuous labeling without product pause. It is the most suitable tamper proof & corner labeling product within the market.

Human Technology Adjustment, No Need For Complicated Part Change Over

The well designed structure efficiently adjusts the applicator position and related assembly, a complicated part changeover is not required. Through touchscreen it is possible to proceed detail and specific settings. An in-built guide mode and trouble shooting enable both regular staff and temporary personnel to efficiently operate the machine and achieve the production demand.

Monitoring And Management To Ensure Product Perfection

Equipped with production quantity setting and pre-count function for production monitoring purpose. Able to customize and equip detection and warning functions for the production management. Ensuring labeling accuracy precision and meeting strict quality demands.

- The main labeler structure is manufactured from S304 stainless steel with anodized process and high quality aluminum.

- It complies with GMP standard which provides an easy maintenance and a long durable life.

- The mobility castor and stainless steel fixing nut are designed to flexibly move the machinery to support another production line, boosting the investment benefits.

- It provides a wide range adjustment ability by being equipped with a hand wheel mechanism for easy adjustment of the applicator depending on the product.

- In-built instruction and troubleshooting provide learning instructions and a prompt solution for operation problems, reducing the personnel training time and avoiding any shutdown costs.

- 30 lots memory modules to record the best labeling settings for the best productivity.

- Smart label length setting to quickly achieve the perfect position of the label by counter.

- Missing Labl Setting prevents product mislabeling to ensure a product accuracy during the production and fulfill production QC procedures.

- A built-in counter can either run freely keeping track of the number of products labeled to control the production.

- Production preset function stops the labeler automatically when the desired number of products have been achieved, for efficient production management.

- Auto label start up mode when the power is switch on, the machine will enter the labeling setting automatically as the previous run without reset.

- Labeling delay function is ideal for small scale adjustmenst and can do digital calculations for dispensing speed and position.

Simple to Use

- The mobility castor and stainless steel fixing nut are designed to flexibly move the machinery to support another production line, boosting the investment benefits.

- It provides a wide range adjustment ability by being equipped with a hand wheel mechanism for easy adjustment of the applicator depending on the product.

- In-built instruction and troubleshooting provide learning instructions and a prompt solution for operation problems, reducing the personnel training time and avoiding any shutdown costs.

- 30 lots memory modules to record the best labeling settings for the best productivity.

- Smart label length set to quickly achieve the perfect position of the label by counter.

- Missing label set prevents product mislabeling to ensure a product accuracy during the production and fulfill production QC procedures.

- A built-in counter can either run freely keeping track of the number of products labeled to control the production or to be used as batch mode, stopping the machine automatically when target production has been reached.

- Production preset function stops the labeler automatically when the desired numbers of products have been reached, for efficient production management.

- Auto label start up mode when the power is switch on, the machine will enter the labeling setting automatically as the previous run without reset.

- Labeling delay function is ideal for small scale adjustments and can do digital calculations for dispensing speed and position.

Built to Last

- The main labeler structure is manufactured from S304 stainless steel with anodized process and high quality aluminum.

- It complies with GMP standards which provides an easy maintenance and a long durable life.

Contact Information

Find us here:

ADR AG

Ludwig-Wagner-Straße 19

Wiesloch

69168

Germany

Phone: 06222 938823